When shippers, carriers, and 3PLs are looking to analyze their budgets and find supply chain solutions to cut shipping-related costs, they might consider any number of contributing factors. For instance, a certain percentage of their cargo every year is likely to be lost or stolen en route to its destination. Other items might be damaged due to rough handling, poor roads or driving, or temperature fluctuations. But there’s one question you may not be asking enough: How much time do your assets spend stuck in park?

Let’s take a look at why it’s important to know how much time your cargo spends in idle, and how the Delivery Chain platform and asset trackers can make your assets more secure and reduce costs.

Why Idling Matters

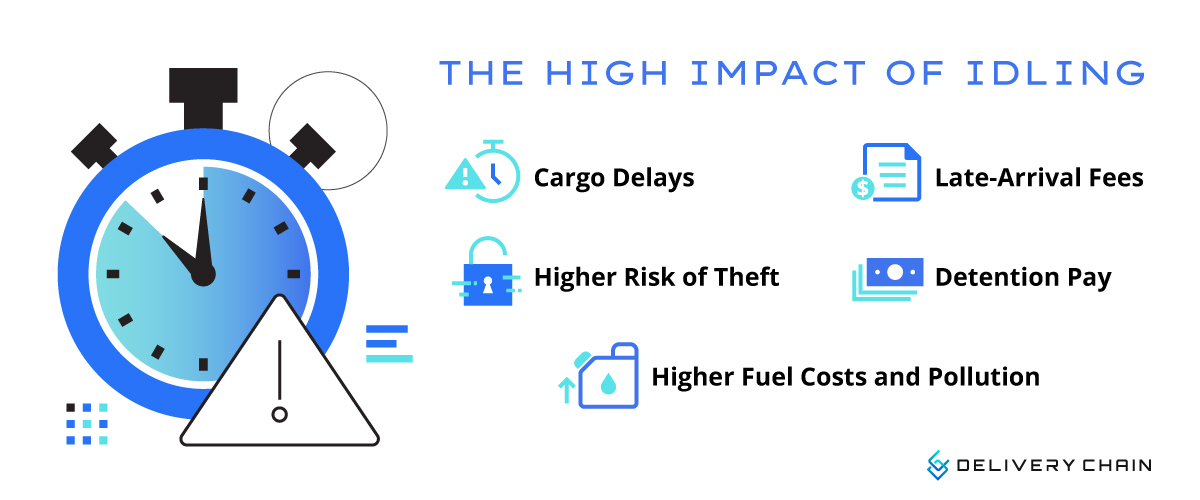

When you’re shipping your cargo, the amount of time it spends idling can make a big difference to your bottom line. There are a number of reasons it’s worth your while to automate tracking and reduce idle time:

- Delays in the arrival of your cargo can cause logistical challenges and leave you with unhappy customers. Accessing pallet-level intelligence® via the Delivery Chain platform can let you know where your pallet is in real time, so that you can be alerted to customizable idle times more quickly. This way, you can contact the carrier and find solutions for potential supply chain problems earlier.

- Your items are at greater risk of theft in the “red zone” within the first 250 miles of the origin of the shipment. If your carrier spends an excessive time idling in this zone, it could be a cause for concern. With the Delivery Chain platform, you can monitor activity in this area particularly careful in order to avert potential theft.

- Shippers can be penalized for late arrivals at big-box stores such as Walmart. Make sure you’re not paying unnecessary fees by reducing idle time.

- 3PLs and shippers can also be charged extra fees for excessive loading and unloading time at warehouses. They receive detention pay after 2 free hours to load or unload for truckload and just 30 minutes for LTL. That’s why they sometimes need proof of entering a delivery facility when they said they did. The Delivery Chain platform tracks the location of your cargo every step of the way, and when you use an asset tracker that’s wired-in to a trailer’s electrical system, you’ll receive even more frequent updates. That way, you can access down-to-the-minute insights on where your cargo was and when.

- Idling vehicles lead to unnecessary spending on fuel, and more negative environmental impacts as a result. In fact, the US Department of Energy reports that idling heavy-duty trucks burn around 0.8 gallons of fuel per hour. It’s estimated that idle time for trucks around the United States consumes as much as 1 billion gallons of fuel every year and costs carriers around $3 billion. This emits a total of 11 million tons of carbon dioxide every year. So when idle time is reduced, not only does the cost of shipping go down — we all do a little something to prevent climate change.

Supply Chain Solutions for Your Organization

Delivery Chain’s platform offers a multi-faceted approach to all these problems above. It starts with monitoring assets with IoT. Next, it leverages the automatic notification system to keep you informed of all events related to your shipment. What’s unique about Delivery Chain are the robust Trigger Action Groups (TAGs) can be created to specific shipper needs.

At Delivery Chain, we know that your freight is safer in motion than sitting idle. That’s why the Delivery Chain platform offers idle alerts. All of this empowers you to take action sooner and make more informed decision, both during the shipment and after it’s complete.

If you’re in supply chain and are curious how automation, AI, or other software can boost your business processes, reach out to Delivery Chain today to learn how to simplify logistics with smart technology.